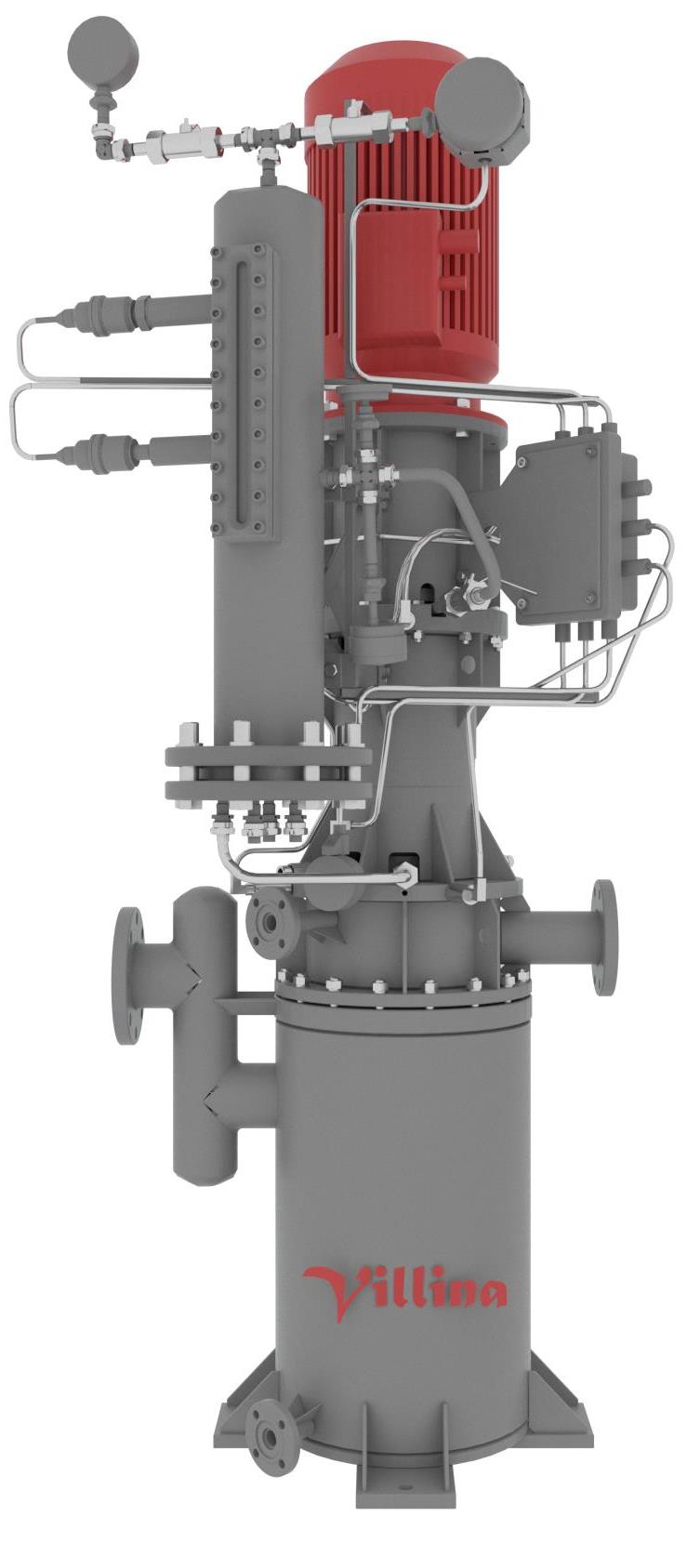

Vertical pumps with mechanical seals

- the vertical self-priming version allows connection of pipes to the existing pump lines group assembly.

- a combined seal with a magnetic coupling or a tandem mechanical seal;

- pumping of contaminated liquids with particle size of 3 to 12 mm;

- a unified design allows you to change the technical parameters of the pump without changing its overall and mounting dimensions;

- UNINTERRUPTED PUMP OPERATION IN THE EVENT OF DRY RUNNING

Main specifications

- Pump rate ranges: 0,15 to 220 m3/h;

- Head: up to 400 m;

- Temperature of the pumped fluid: -50°С to +420°С.

Villina-VS1-M type pumps are designed for use in oil and gas and chemical industries for transit of explosive and highly flammable liquids as well as corrosive media and natural gas liquids. A distinctive feature of these pumps is the ability to transit contaminated liquids with particle size of 3 to 12 mm (depending on the pump rate).

Villina-VS1-M type valves are designed for pumping liquids with head of up to 150 meters and pump rate of up to 100 m3/h. "X" (carbon steel), "H" (stainless steel) or "E" (molybdenous steel) material combinations are selected by Villina employees in accordance with the Customer's specification. The density of the pumped liquid can reach 2,000 kg/m3, the viscosity can be equal to 160 cSt. The temperature range is from -50°C to +400°С.

Explosion-proof Villina-VS1-M pumps are marked with "Ex", they are equipped with combined explosion protection which limits the power of sparks, isolates the electrical circuits from explosive mixtures, reduces the likelihood of electric spark striking, contains a potential explosion in an explosion-proof enclosure.

The climatic version for moderate and cold climate and for cold climate (1-4) renders Villina-VS1-M pumps operable at temperatures from -60°С to +40°С and exempts the Customer from the expenses for building and maintaining special rooms.

When manufacturing a pump, the positions of the suction and discharge pipes along the pump axis can be selected at an angle from 0 to 360 degrees in increments of 45 degrees relative to each other, and the position of the suction pipe along the axis can be changed at the request of the Customer. This makes the pump lines assembly much simpler. Special outlet adapters are provided in the pump for bleeding air before the start, and for draining the residue of the pumped fluid before maintenance.

Vertical Villina-VS1-M pumps occupy an average of 5 to 10 times less space than horizontal pumps. The engine is mounted on top of the pump body by means of a flange connection. This makes it easy to dismantle and reinstall when servicing the pump unit. To increase the average life and the overhaul life, the engines made by VEMZ and AVV are equipped with SKF rolling-element bearings. These bearings can be equipped with temperature and vibration monitoring devices, as assigned by the Customer.

Villina pump motors are also designed for use with a frequency converter. This allows the user to adjust the rotation speed and to change the head and flow rate of the pump unit within the performance range.

Features of Villina-VS1-M type pumps

- the multi-stage design of the pump, machining of the impeller and installation of a bypass valve on the pump allows for a pump design with various combinations of pump rate and head values;

- impeller blades with curved surfaces create an angle of attack varying along the inlet edge and partially allow for switching to the laminar mode of wall-adjacent flow on their surface and provide more efficient deflection of liquid to the periphery;

- a closed type impeller has a higher efficiency and longer service life compared to open and semi-closed impellers;

- bell-type fit of the impellers on the pump shaft precisely keeps the geometric position of the impellers with respect to the guide vanes;

- groove seals with floating rings increase the efficiency of the pump;

- the pump seal is a tandem mechanical seal. The mechanical seal support system is combined with the rolling-element bearing lubrication system;

- the pump rotor rotates in the rolling-element bearings. The upper double-angular rolling-element ball bearing securely fixes the pump rotor preventing its axial movement and takes up residual axial force, most of which is unloaded on the impellers by means of a groove seal on the main disk;

- thermal expansion of the pump parts is compensated for by the position of the wet end of the pump in the barrel body and the absence of obstacles in the event of upward expansion.

Villina-VS1-M series pumps have wide configuration options with respect to the basic design:

- the barrel body can be replaced with a bend inlet, or the pump can be mounted on the Customer’s container;

- a worm screw can be installed to increase the suction capacity;

- a thermal barrier fed by an external source of coolant can be installed to reduce the heating of the barrier fluid and to stabilize acceptable temperature conditions of the bearings;

- a self-priming version by means of an increased volume of the barrel body;

- a version of the pump with a magnetic coupling instead of the upper mechanical seal is possible, while keeping the support system. This ensures the integrity of the wet end of the pump and 100% tightness of the pump not only concerning the pumped fluid, but also the barrier fluid.

You can combine the options above when ordering a pump, and you will get the most suitable pump version.

Villina-VS1-M series pumps are equipped with counter flanges with bolting and gaskets, a spare parts kit for 2 years of operation, a video on commissioning, assembling and disassembling of the pump unit. After a unit has been commissioned, Villina employees carry out inspection and provide comprehensive advisory assistance during the entire life of the pump through the service monitoring program.

ADDITIONALLY

As per the Customer's order, technical experts of Villina will additionally select and include in the supply package of vertical pumps with magnetic couplings a startup protection device, shut-off and control valves (SCV), a variable speed drive (VSD), heating and thermal insulation devices, instrumentation and control.

Extended warranty may be provided by the manufacturer. Direct supply of spare parts for Villina pumps from the manufacturer’s warehouse will eliminate down time of your production.