Horizontal pumps with magnetic coupling

- Purpose: transit of corrosive, toxic, explosive and flammable fluids;

- Pump rate ranges: 1.8 to 1080 m3/h;

- Head ranges: 3.2 to 250 m;

- Seal type: a magnetic coupling with a sealing sleeve made of Hastelloy alloy (standard version) ensures 100% tightness;

- Climatic version: for moderate and for moderate and cold climate;

- Temperature of the pumped fluid: up to plus 350°С;

- Shaft speed: 1,450 or 2,900 rpm;

- Structural design: ОН-2 single-stage back pull-out pump according to API 610.

Scope of application

The Villina GNGC series horizontal canned centrifugal pumps with magnetic couplings are widely used in oil and gas companies of Russia and its neighbouring countries for transit of explosive and flammable, toxic and corrosive fluids.

The horizontal arrangement allows the use of a GNGC as a replacement for technically obsolete and physically worn pumps without significantly changing the geometry of the location and pump lines group assembly systems.

100% tightness, structural design in accordance with API 610, 685 (ISO 13709) standards and explosion-proof design of GNGC pumps are approved by design institutes and Rostekhnadzor for use in projects for modernization, reconstruction or construction of new facilities.

Design and principle of operation

GNGC horizontal pumps with magnetic couplings provide for axial position of the suction pipe and radial position of the delivery pipe. The motor and pump body are mounted on supports (OH 2 according to API 610), the drive shaft of the motor is connected to the pump shaft through an elastic laminated coupling. High-quality ceramic sleeve type bearings are used to fit the shaft inside the wet end of the pump. To provide stability and to compensate for axial forces, SKF block bearings serve as the supports for the drive shaft, which rule out axial play and lateral runout, which makes GNGC horizontal pumping units resistant to frequent starts and stops during periodic operation.

GNGC pumps comprise solid-cast enclosed impellers of high efficiency and high structural integrity. Bell-type fit of the impeller on the shaft precisely keeps the position of the impeller on the shaft. Villina pump impeller blades have curved surfaces.

The pumped fluid is supplied along the axis of rotation to the impeller and enters the interblade channel. The centrifugal force of the rotating impeller drives the fluid into the guide vanes (the "volute"). The guide vanes convert the kinetic energy of the flow into potential pressure energy. The fluid enters the delivery pipe under pressure. The GNGC pumps use guide vanes with working surfaces of special geometry that convert the flow energy with lowest friction losses.

The technology used in machining the impeller helps to move the working point of the GNGC pumping unit as close as possible to the head and pump rate values required by the customer’s technical specification with virtually no loss of pump efficiency.

GNGC horizontal single-stage centrifugal pumps with magnetic couplings are equipped with foreign (Siemens, ABB) and domestic (Vladimir Electromotor Plant) general industrial or explosion-proof electric motors manufactured using SKF bearings. All the motors are designed for operation using digital frequency drives for pump parameter adjustment and can be equipped with temperature sensors for rolling-element bearings and coils.

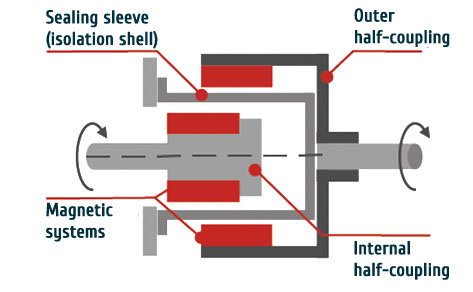

Tightness of GNGC pumps

The tightness of GNGC pumps is ensured by a magnetic coupling of the separatory sleeve between the magnetic half couplings provided for in the design. Leakage of the pumped fluid is impossible.

The magnetic coupling is designed with a torque backup up to 40%. Before mounting the coupling on the pump unit the coupling is tested for "separation". The half couplings have an enclosed capsular design.

Sealing sleeve made of high-strength alloy steels.

Double "temperature margin" for protection against demagnetization due to overheating: permanent magnets with Curie point more than 100°C higher than the maximum operating fluid temperature are used, while the temperature control sensor of the sealing sleeve is triggered when the maximum permissible temperature is exceeded by 20 to 50°C.

Economic effect of the use of GNGC pumps

The use of Villina GNGC series pumps eliminates or significantly reduces some capital and operational costs:

- for supply, maintenance and repair of cooling loops in the pump house;

- for procurement of seal support systems and barrier fluid systems;

- for purchasing repair kits for seals (magnetic coupling service life is 20 years);

- for construction of additional supply and exhaust ventilation systems (as a result of 100% tightness, no occurence of leaks and explosive steam-and-gas mixtures).

GNGC horizontal pumps with magnetic couplings are modern quality standards implemented in a time-tested design.