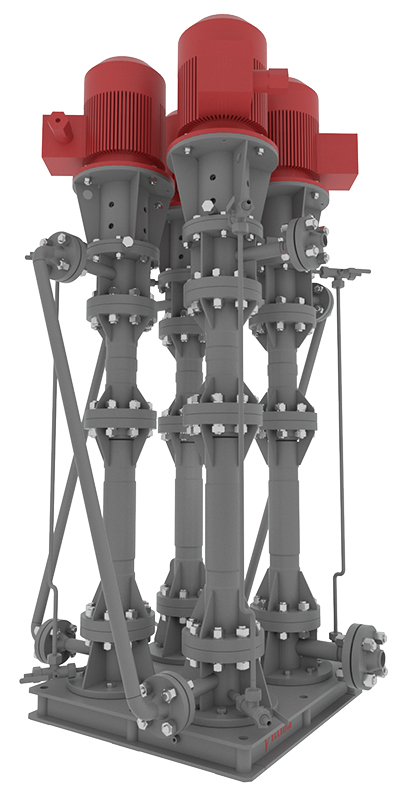

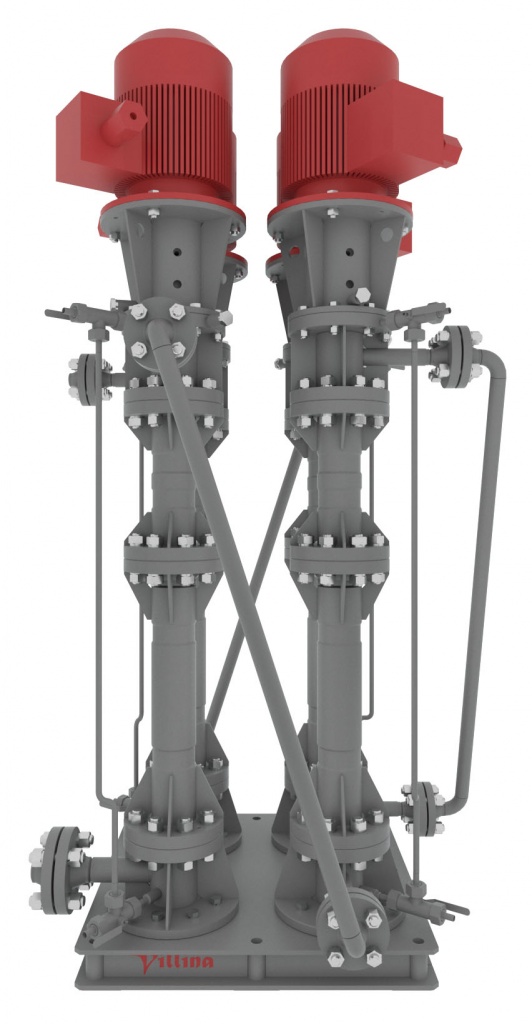

Combination pumps

Centrifugal combination pumps consist of a number of series-connected electric pump sections mounted on one bedplate. Pump rate ranges: up to 220 m3/h; head ranges: up to 3,000 m. Each section consists of a canned pump and an electric motor (pump drive).

Performance specifications

- Purpose: transit of corrosive, toxic, explosive and flammable fluids;

- Pump rate ranges: up to 220 m3/h;

- Head ranges: up to 3,000 m;

- Seal type: a magnetic coupling according to API 685 with a sealing sleeve made of non-magnetic material ensures 100% tightness;

- Climatic version: for moderate and for moderate and cold climate in accordance with GOST 15150;

- Operation placement category: 1, 2, 3, and 4 according to GOST 15150;

- Temperature of the pumped fluid: -50°С to +420°C;

- Shaft speed: 1,000 to 3,000 rpm;

- Structural design: vertical type with the motors mounted on a flanged connection.

The design of an electric pump section is similar to the design of a standard vertical electric pump with a GNVC series magnetic coupling, which allows for the use of already proven technical solutions:

The design of an electric pump section is similar to the design of a standard vertical electric pump with a GNVC series magnetic coupling, which allows for the use of already proven technical solutions:

- impeller blades with curved surfaces create an angle of attack and partially allow for switching to the laminar mode of wall-adjacent flow on their surface and provide more efficient deflection of liquid to the periphery;

- a closed type impeller has a higher efficiency and longer service life compared to open and semi-closed impellers;

- bell-type fit of the impeller on the pump shaft precisely keeps the geometric position of the impeller with respect to the guide vanes;

- the vertical position of the shaft resting on a heavy-duty carrying cushion in the vertical plane, and sleeve type bearings in the horizontal plane help prevent sagging of the shaft, as for instance, in the horizontal design of the pump, and play and runout;

- the use of sleeve type bearings made of silicon carbide (SiC) based materials, lubricated by the pumped medium, allows the user to avoid using grease;

- transmission of torque to the pump shaft without mechanical engagement using a magnetic coupling ensures the integrity of the wet end of the pump and 100% tightness without additional expenses on cooling circuits, installation and maintenance of systems with seal fluid.

Advantages of combination pump units

The use of several series-connected sections in one unit has a number of advantages compared to standard electric pumps.

- the ability to provide greater pressure with similar performance (pump rate);

- installation of several low-voltage electric motors instead of one high-voltage motor, which ensures lower loads on the power supply network of the operating company;

- installation of smaller magnetic couplings ensures:

- less heating in the installation area, which contributes to longer-term operation without cooling;

- less sensitivity to voltage swings of the power supply network of the operating company;

- less possibility of breakdown in the event of rotor jam.

- the possibility of separate installation of the unit, which allows for the use of mechanisms of lower carrying capacity.

Scope of application

Since combination units consist of several standard vertical GNVC series electric pumps with magnetic couplings, they are also used in oil and gas and chemical industries for transiting neutral, corrosive, toxic, as well as explosive and flammable liquids in stationary conditions, the vapors of which can form explosive mixtures with air of categories IIA, IIB, IIC, groups T1, T2, T3, T4 according to GOST R IEC 60079-20-1.

Explosion-proof units are used in hazardous areas of class 1 and 2 according to GOST 31438.1, GOST IEC 60079-10-1, and in hazardous areas of class B-I, B-Ia, B-Ib, B-Ig, in accordance with "Electric installation code" (EIC).

Characteristics of liquids allowed for pumping: temperature from -50°С to +420°С, viscosity up to 35 cSt, density 2,000 kg/m3 maximum, mass concentration of solid non-abrasive inclusions up to 0.2%, size 0.2 mm maximum.

Material combinations are selected by Villina employees in accordance with the Customer's specification.