Magnetic coupling

Magnetic couplings are used as transmission mechanisms in modern pumps, which makes it possible to obtain a qualitatively new 100% tight device without making essential changes to the design of the electric drive and the wet end of the pump.

At present Villina offers GNVC, GNGC and GNVC-P series vertical, horizontal and semi-submersible centrifugal pumps with magnetic couplings, designed for pumping explosive and flammable, toxic and corrosive fluids (petroleum products, alkalis, acids, alcohols, etc).

Purpose

Magnetic couplings for Villina centrifugal pumps allow for transmission of torque from the electric motor to the pump shaft using magnetic fields generated by permanent magnets instead of mechanical engagement devices. At the same time, there is no need to withdraw the shaft from the pump wet end to the drive device, therefore the wet end can be made in the form of a completely sealed system free of leaks which are typical for pumps with mechanical shaft seals.

Configuration and principle of operation of the magnetic coupling

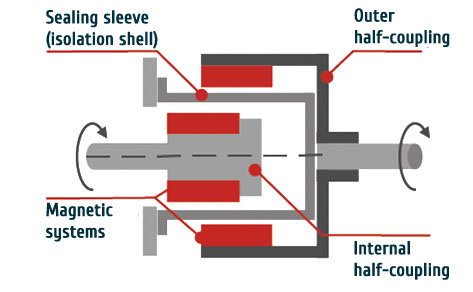

Villina leaktight magnetic couplings consist of two half couplings, the driving and the driven half couplings, and a sealing sleeve (isolation shell) between them.

The sealing sleeve made of stainless steel or Hastelloy high-strength is able to withstand pressures over 5 MPa;

The bodies of the driving and driven half couplings are made of stainless steel and are located on the motor shaft and on the pump shaft, respectively. High-coercive permanent magnets based on NdFeB (neodymium-iron-boron) or SmCo (samarium-cobalt) rare-earth metal compositions are fixed in steel ferrules (capsules) using special adhesives. The magnets interact through the sealing sleeve and transmit torque without contact.

A disassembled magnetic coupling

Increased reliability of Villina magnetic couplings

The weakest points of permanent magnets are limitations on operating temperature and high fragility of the alloys.

The magnets of Villina magnetic couplings are securely protected from external mechanical loads by steel ferrules (Figure 1).

In order to protect the magnets from overheating and loss of magnetic properties Villina magnetic couplings are provided with a temperature reserve:

- NdFeB (neodymium-iron-boron) with Curie point of about +350°С is used in Villina magnetic couplings at temperatures from -60 to + 240°C (the temperature reserve is about 100°C);

- SmCo (samarium-cobalt) with Curie point of about +350°С is used at operating temperatures up to +350°С (the temperature reserve is over 100°C).

To increase reliability and to extend the design life to 20 years, Villina centrifugal pump design includes a magnetic coupling cooling system without additional devices. Cooling is carried out by the pumped fluid through a special linear hole in the pump shaft, which removes heat from the sealing sleeve together with the pumped fluid from the high-pressure area to a lower pressure area.

To control the temperature of the magnetic coupling in Villina pumps, an explosion-proof heat sensor (Pt100) is used as standard which takes readings from the outer surface of the sealing sleeve.

The transfer of the maximum required torque by the Villina magnetic coupling is guaranteed by its reserve of up to 40% envisaged in the design and testing of the coupling for "breakdown" at a special test facility.