Vertical pumps with magnetic couplings

- Purpose: transit of corrosive, toxic, explosive and flammable fluids;

- Pump rate ranges: 0,15 to 220 m3/h;

- Head ranges: up to 600 m;

- Seal type: a magnetic coupling according to API 685 with a sealing sleeve made of Hastelloy alloy (standard version) ensures 100% tightness;

- Climatic version: for moderate and for moderate and cold climate;

- Temperature of the pumped fluid: up to plus 420°С;

- Shaft speed: 2,900 rpm;

- Structural design: vertical type with the motor mounted on a flanged connection;

- Advantages: in comparison with back pull-out pumps, 3 to 5 times less production space is required for placement; the multi-stage design allows any combination of pump rate and head values.

STOCK AVAILABLE: GNVC-E-25-60-H-UHL2 vertical multi-stage centrifugal electric pump unit with a magnetic coupling:

STOCK AVAILABLE: GNVC-E-25-60-H-UHL2 vertical multi-stage centrifugal electric pump unit with a magnetic coupling:

- power 15 kW, explosion-proof type

- pump rate 25 (17-30) m3/h

- head 60 metres

- material combination Х (carbon steel)

- climatic version: for moderate and cold climate;

- placement category 2 (under cover)

Scope of application of vertical pumps

Villina produces GNVC series (vertical multi-stage centrifugal pump) vertical pumps with magnetic couplings of explosion-proof and general industrial versions. GNVCs are high-speed pumps with a shaft rotation speed of 3,000 rpm and are intended for use in the oil and gas and chemical industries. On the recommendation of Rostekhnadzor and in accordance with the permit for use, GNVC series pumps are used for pumping explosive, flammable liquids, as well as corrosive fluids and natural gas liquids.

GNVC multi-stage valves with magnetic couplings are designed for pumping liquids with head of up to 250 meters and pump rate of up to 200 m3/h. "X" (carbon steel), "H" (stainless steel) or "E" (molybdenous steel) material combinations are selected by Villina employees in accordance with the Customer's specification. The density of the pumped liquid can reach 2,000 kg/m3, the viscosity can be equal to 35 cSt. The temperature range is from -50°C to +350°С.

Design and principle of operation

Explosion-proof GNVC pumps are marked with "Ex", they are equipped with combined explosion protection which limits the power of sparks, isolates the electrical circuits from explosive mixtures, reduces the likelihood of electric spark striking, contains a potential explosion in an explosion-proof enclosure.

The climatic version for moderate and cold climate and for cold climate (1-4) renders GNVC pumps operable at temperatures from -60°С to +40°С and exempts the Customer from the expenses for building and maintaining special rooms.

The suction and discharge nozzles can be located at an angle of 0, 90, 180 and 270 degrees relative to each other on a horizontal plane, and this makes the pump lines assembly much simpler. Special outlet adapters are provided in the pump for bleeding air before the start, and for draining the residue of the pumped fluid before maintenance.

Vertical GNVC pumps are mounted on base plates and occupy an average of 5 to 10 times less space than horizontal pumps. The engine is mounted on top of the pump body by means of a flange connection. This makes it easy to dismantle and reinstall when servicing the pump unit. To increase the average life and the overhaul life, the engines made by VEMZ and AVV are equipped with SKF rolling-element bearings. These bearings can be equipped with temperature monitoring devices, as assigned by the Customer.

Vertical GNVC pumps are mounted on base plates and occupy an average of 5 to 10 times less space than horizontal pumps. The engine is mounted on top of the pump body by means of a flange connection. This makes it easy to dismantle and reinstall when servicing the pump unit. To increase the average life and the overhaul life, the engines made by VEMZ and AVV are equipped with SKF rolling-element bearings. These bearings can be equipped with temperature monitoring devices, as assigned by the Customer.

Villina pump motors are also designed for use with a frequency converter. This allows the user to adjust the rotation speed and to change the head and flow rate of the pump unit within the performance range.

Reliability and a very long design life of 20 years are due to the use of exclusively modern technical solutions in the pump design proven in practice:

- the multi-stage design of the pump allows for any combination of pump rate and head values;

- impeller blades with curved geometrical surfaces create an angle of attack and partially allow for switching to the laminar mode of wall-adjacent flow on their surface and provide more efficient deflection of liquid to the periphery;

- a closed type impeller has a higher efficiency and longer service life compared to open and semi-closed impellers;

- bell-type fit of the impeller on the pump shaft precisely keeps the geometric position of the impeller with respect to the guide vanes;

- the vertical position of the shaft resting on a heavy-duty carrying cushion in the vertical plane, and sleeve type bearings in the horizontal plane help prevent sagging of the shaft, as for instance, in the horizontal design of the pump, and play and runout;

- the use of sleeve type bearings made of silicon carbide (SiC) based materials, lubricated by the pumped medium, in the wet end of the pump allows the user to avoid using grease;

- transmission of torque to the pump shaft without mechanical engagement using a magnetic coupling ensures the integrity of the wet end of the pump and 100% tightness without additional expenses on cooling circuits, installation and maintenance of systems with seal fluid.

API 685 magnetic coupling

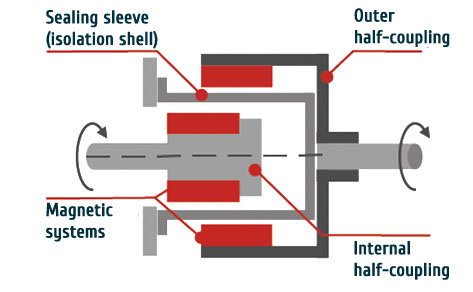

The main parts of magnetic couplings used in GNVC series vertical pumps are the driving (external) and the driven (internal) half couplings, and a sealing sleeve between the half couplings.

The exceptional reliability of Villina magnetic couplings is the result of a high-tech design:

- the enclosed capsular design of the half couplings (enclosed body) secures the magnetic systems from environmental effects;

- the use of special adhesives allows for fast fixture of domestically produced permanent magnets based on rare-earth elements on the half coupling ferrules;

- double protection against overheating and demagnetization is implemented using the temperature sensor of the sealing sleeve, which is triggered when the maximum acceptable operating temperature is exceeded by 20 to 50°C, with the use of magnets with Curie point of more than 100°C higher than the maximum acceptable operating fluid temperature;

- the sealing sleeve made of high-strength Hastelloy alloys is constantly cooled by the pumped medium; increased cooling efficiency is achieved by draining the liquid from the high-pressure area near the sealing sleeve through a linear access hole in the pump shaft to the low-pressure area in the middle and lower part of the pump body;

- the magnetic coupling is designed with a torque backup up to 40% and is tested for "separation" before mounting on the pump unit.

The use of a magnetic coupling renders the alignment and control of the alignment of the pump and motor shafts redundant and helps avoid the perennial problem of tightness reduction when stationary and rotating faces in pumps with tandem mechanical seals are worn.

Villina GNVC series pumps are equipped with counter flanges with bolting and gaskets, a spare parts kit for 2 years of operation, a video on commissioning, assembling and disassembling of the pump unit. After a unit has been commissioned, Villina employees carry out inspection and provide comprehensive advisory assistance during the entire life of the pump through the service monitoring program.

Additionally

As per the Customer's order, technical experts of Villina will additionally select and include in the supply package of vertical pumps with magnetic couplings a startup protection device, shut-off and control valves (SCV), a variable speed drive (VSD), heating and thermal insulation devices, instrumentation and control.

Extended warranty may be provided by the manufacturer. Direct supply of spare parts for Villina pumps from the manufacturer’s warehouse will eliminate down time of your production.